-

Can 3D printing replace molds? Yes, with a 60% cost drop.

Here are some cases demonstrating how 3D printing can reduce mold costs:Automated Dynamics: Automated Dynamics used Stratasys' FDM technology to fabricate helicopter blade prototypes. By using sol

2025/02/21 3D printing

-

Gas - mold relationship in injection molding

The generation of gas during injection molding is intricately linked to the mold across multiple aspects, mainly covering mold design, manufacturing & processing, and usage & maintenance.Mold

2025/02/19 Gas - mold relationship

-

What is the cause of shrinkage of injection parts?

The reasons for the formation of shrinkage holes in injection molded parts are rather complex, mainly involving materials, molds, processes, etc. The following is a specific analysis:I. Material Facto

2025/02/17 Plastic material

-

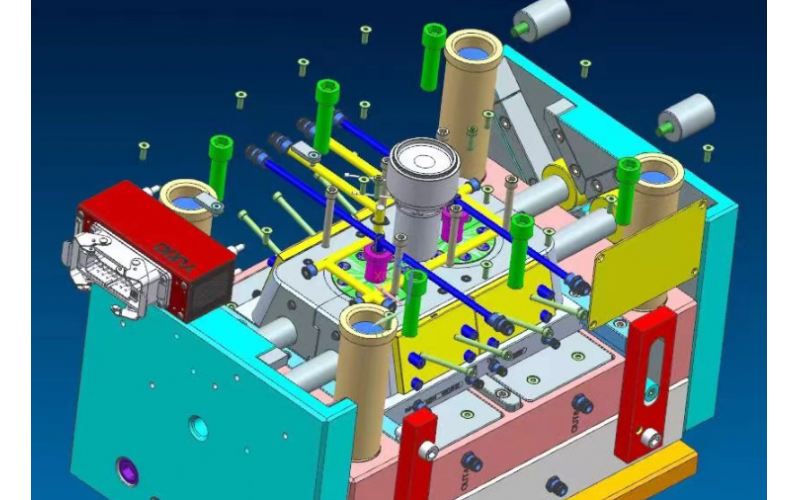

Factors affecting the quality of injection moulds

I. Injection Mould DesignProduct Analysis & Optimization:Prior to mould design, thoroughly analyze the product. Consider its structure, accuracy needs, appearance, and usage scenarios. For complex

2025/02/15 Mold material

-

What is the reason for the injection molding product fusion line

The reasons for the formation of fusion lines in injection molding products are multifaceted, mainly related to factors such as the characteristics of plastic materials, mold design, injection molding

2025/02/13 Injection molding product

-

Precautions and solutions for burnt injection molding products

Burnt injection - molded products are a common and challenging issue in injection molding, which affects the appearance, performance, and lifespan of products. The following elaborates from four aspec

2025/02/11 Injection molding products

-

What is glass fiber reinforced plastic?

Glass Fiber Reinforced Polymer (GFRP), commonly known as fiberglass reinforced plastic, is a kind of fiber-reinforced composite material made with synthetic resin as the adhesive matrix and glass fibe

2025/02/09 glass fiber reinforced plastic

-

What is the three-stage injection molding process

1. Complex Geometry of Molds and PartsInjection - molded parts are often thin - walled structures with complex shapes. The thin - walled structure, combined with high injection speeds, results in high

2025/02/07 Three-stage injection molding