In modern manufacturing, precision injection molding is a crucial technology. It's widely used in fields demanding high - precision plastic products, such as aerospace, automotive, precision instruments, medical, and electronics.

Precision injection molding is an advanced process using injection - molding machines to produce plastic products. It can control product dimensional accuracy within 0.01 - 0.001mm, far more precise than conventional injection molding. For example, in high - end electronics, components need micron - level accuracy for proper functioning.

High Dimensional Accuracy: Product dimensional deviations are usually within 0.03mm. In automotive fuel injection system parts, small deviations can affect engine performance.

High Geometric Accuracy: Shape and position tolerances like flatness, perpendicularity, and coaxiality are strictly controlled. In optical instrument lens holders, small errors can degrade imaging quality.

Good Surface Quality: Products have high surface finish with no obvious defects. This is vital for products like high - end phone cases, enhancing aesthetics and user experience.

Strong Performance Stability: Mechanical and physical properties remain stable across batches and environments. Medical syringes must maintain stable performance for safety.

Materials: Plastic shrinkage, including thermal, elastic, plastic, post - shrinkage, and aging shrinkage, affects precision. Crystalline resins' shrinkage is influenced by mold temperature, while orientation shrinkage relates to injection pressure and speed.

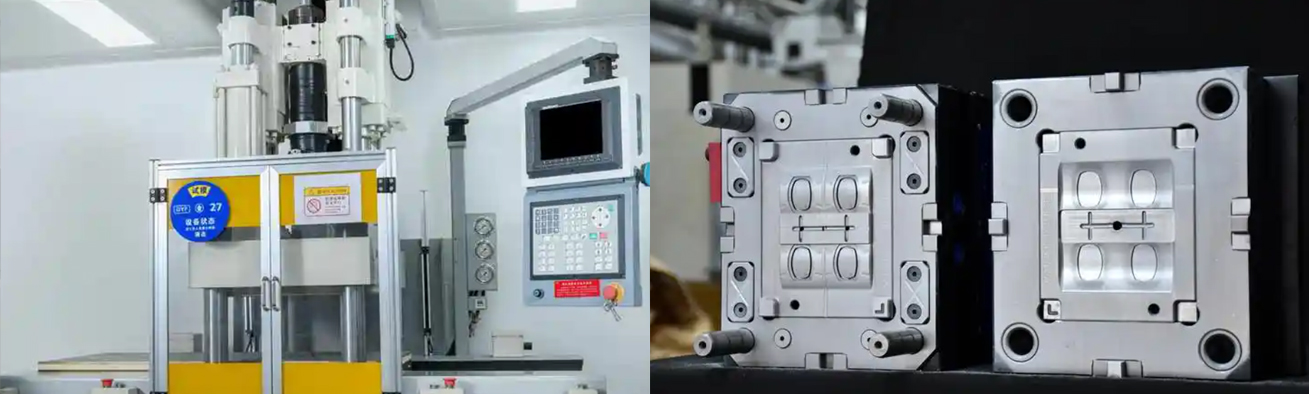

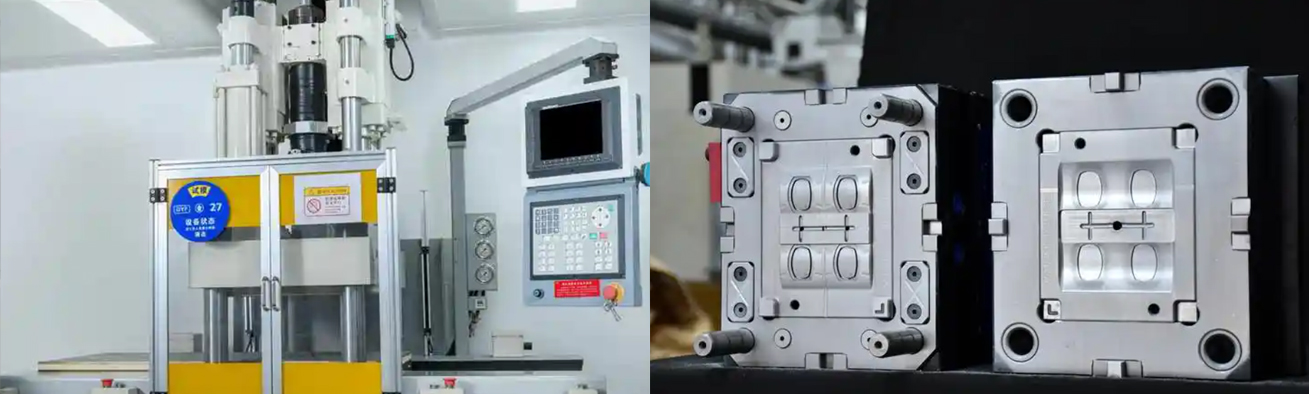

Molds: High - quality steel like NAK80 and 718H is used. Fewer cavities, short and smooth runners are preferred. Mold dimensional, positioning, and parting - surface accuracies determine product precision, with mold tolerances usually within 1/3 of product tolerances.

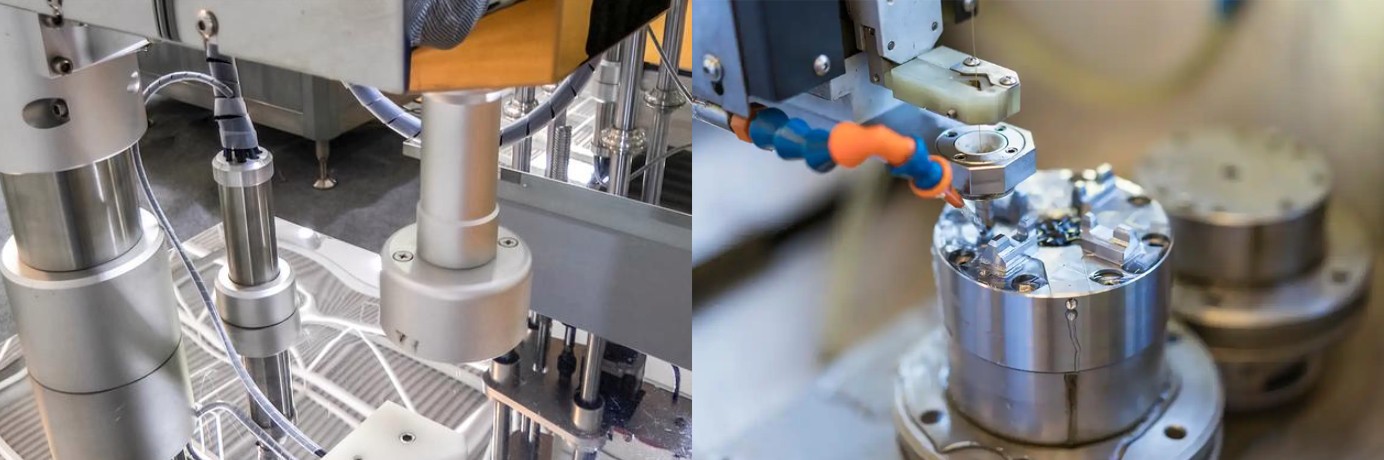

Equipment: Precision injection molding machines with closed - loop control of injection pressure, speed, temperature, and metering are needed. All - electric injection molding machines offer better control and accuracy.

Process: Multi - stage injection and precise mold temperature control are key. Injection parameters are adjusted according to product shape and size. Mold temperature is controlled within ±1℃ for uniform cooling.

Environment: Temperature, humidity, and dimensional creep in the usage environment can affect product precision. Suitable materials and processes are chosen to ensure stability.

Equipment: Injection pressure ≥25MPa, injection speed ≥300mm/s, mold opening/closing position accuracy ≤0.03mm/≤0.01mm, injection position accuracy ≤0.03mm, tie - rod force balance ≤1%, pre - plasticizing position accuracy ≤0.03mm, template balance ≤0.03mm (zero clamping force)/≤0.005mm (max clamping force), and barrel/screw temperature control accuracy ≤±0.5℃.

Mold Design: Design reasonable cavity layouts and runner systems for uniform filling. Set up proper cooling systems for even temperature distribution. Use high - precision parts and advanced manufacturing processes.

Molding Process Parameters: Control injection volume precisely. Set appropriate holding pressure and time to compensate for shrinkage. Keep mold temperature within ±1℃.

Aerospace: Light - weight and high - precision parts, like aircraft interiors, are made using this technology for better fuel efficiency and environmental adaptability.

Automotive: Critical parts such as sensor housings, dashboards, and gears require high precision for reliable vehicle operation.

Precision Instruments: Optical instrument housings and microscope components demand high accuracy for proper function.

Medical: Products like catheters, syringes, and dentures need high precision and safety to meet medical standards.

Electronics and Communication: Miniaturized and high - performance products like phone cases and chip packages are produced with precision injection molding.

Precision injection molding is essential in modern manufacturing. With technological advancements and growing market demands, it will continue to innovate and provide better manufacturing solutions.